Excavator VS Skid Steer - Which is better?

When it comes to heavy machinery in construction and landscaping, two names often come up in discussions: the skid steer and the excavator. Both are powerful tools that serve different purposes on the job site, but understanding their differences and knowing when to use each can significantly impact efficiency and productivity. Let's delve into the comparison between these two machines to help you make an informed decision for your next project.

Excavator |

Skid Steer |

|

|

What is an Excavator?

An excavator is a type of heavy machinery with a hydraulic arm and dozer blade, designed for excavation, landscaping and general ground clearance projects. The hydraulic arm extends for improved digging and usually features rubber or steel tracks to maximize traction with the ground. Excavators are also available with wheels, which are more commonly known as rubber ducks. Wheeled excavators are usually favored in urban environments where manoeuvring on roads is essential. The dozer blade adds additional stability when digging and can be used for simple ground levelling tasks.

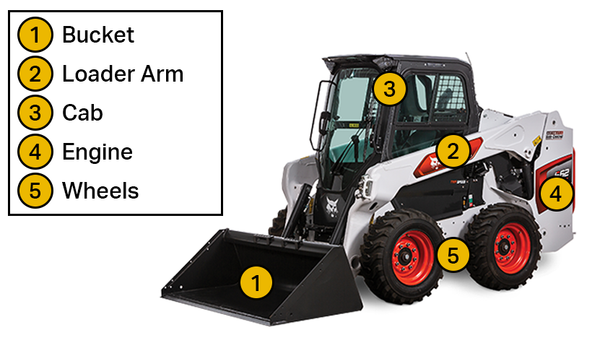

What is a Skid Steer?

A skid steer is a compact, heavy-duty machine with hydraulic arms, designed for bulk moving and to reduce manual labor. Also known as skid steer loaders or skid loaders, the skidsteer is commonly used across construction and landscaping projects for transporting loose or bulky material. Skid steers run on 4 wheels that can be controlled independently of each other, this allows the operator to manoeuvre in tight spaces with ease. A skid steer is also available with tracks, which is more commonly known as a track loader. The tracks increase ground contact, compared to the wheels, making it ideal for more challenging environments, like uneven or incline surfaces.

When Should You Use an Excavator or a Skid Steer?

Best Uses of an Excavator:

- Site Preparation: Before construction begins, excavators are used to clear and level the land, using attachments like ripper teeth and land rakes to remove obstacles like trees and rocks, and prepare the site for building foundations.

- Foundation Digging: Excavators are essential for digging foundation trenches for buildings, bridges and other structures. Their ability to excavate to precise depths and dimensions is crucial, this is achieved via the wide range of bucket widths available.

- Construction: Excavators can now be used for jobs beyond just digging and grading, they are now used for concrete pouring and unloading pallets of materials from trucks.

- Demolition: Equipped with specialized attachments like jack hammers or demolition shears, excavators are used to break concrete, demolish old structures and remove debris from construction sites and quarries.

- Utility Installation: Excavators are used to dig narrow trenches for installing electrical cables and pipes for water and sewage. And are also commonly used for digging irrigation for flower beds and green houses.

- Dredging: Excavators fitted with dredging attachments like rake riddle buckets are used to remove silt, mud, and debris from rivers, ponds and lakes, to help clear blockages and maintain water flow.

- Landscaping: Mini excavators are usually paired with rakes and tilting buckets in landscaping projects for tasks such as clearing overgrown plants, shaping terrain and creating ponds or water features.

Best Uses of a Skid Steer:

- Landscaping: Whether it's ground levelling or moving heavy materials like soil, gravel or mulch, skidsteers with general purpose buckets are ideal for landscaping projects. Their compact size allows them to navigate yards and tight spaces with ease.

- Snow Removal: Equipped with snow blades or snow pushers, skid steers are efficient machines for clearing snow from sidewalks, driveways, parking lots and smaller roads. And can also be fitted with salt spreaders to help prevent ice.

- Agriculture: Skid loaders are commonly used on farms for a variety of tasks such as loading and unloading supplies, moving hay bales, cleaning animal pens and even ploughing fields in smaller operations.

- Demolition: With the right attachments like jack hammers or dozer blades, skid steers can be used in demolition projects for breaking concrete, tearing down structures, and clearing debris.

- Forestry: In forestry operations, skid steers loaders can be fitted with attachments like flail cutters and log grapples for clearing brush, moving logs and maintaining trails.

- Material Handling: Skid steers are frequently used with pallet fork attachments in warehouses, factories and shipping yards for loading and unloading pallets, stacking materials and transporting goods over short distances.

Excavator VS Skid Steer Operational Comparison

1. Versatility

When considering versatility, the skid steer stands out for it's ability to handle a wide range of task, from land clearance to material handling, across a range of environments. The general purpose bucket usually seen on a skidsteer allows it to comfortably move large amounts of material with ease. Excavators features a 360-degree cab rotation capability, allowing it to effortlessly access and operate in all directions across the worksite but has limited capabilities when it comes to bulk loading jobs compared to the skid steer.

2. Size and Manoeuvrability

When comparing size and manoeuvrability, it's important to note that excavators can vary in size dramatically compared to skidsteers. Excavators range from 0.5 ton (1,000 lbs) compact mini excavators suitable for navigating tight spaces, to much larger 30 ton (60,000 lbs) excavators designed for extensive construction projects, and even 100 ton (200,000 lbs) excavators designed for excavating quarries. Skid steer loaders typically ranges from 1 ton up to 5 tons (2,000 lbs up to 10,000 lbs). The compact size of skid steers excel their manoeuvrability, enabling them to turn on a dime.

It's worth noting that skid steers equipped with wheels enable them to travel across asphalt and tarmac without causing damage to the surface. Wheeled excavators or compact mini excavators with rubber tracks also have the ability to work on asphalt and tarmac, compared to steel tracked excavators or track loaders that experience limitations in this accessibility due to the risk of surface damage. When it comes to boggy sites, wheeled equipment have accessibility and manoeuvrability issues as the wheels provide less traction. Understanding your terrain and project requirements will help you determine whether the skid steer or excavator is better suited to you.

3. Digging and Lifting Capabilities

When comparing digging and lifting capabilities, both the excavator and skid steer excel in their own rights. Excavators typically have greater reach and digging depth compared to skid steers, making them ideal for large-scale earthmoving projects. While not as powerful at digging, skid steers make up for it with their lifting capabilities. Equipped with a variety of attachments, including forks and buckets, skid steers can efficiently move heavy materials across sites. While excavators specialize in deep digging and precision work, skid steers offer agility and versatility in lifting tasks, catering to different project requirements.

Summary - Which is best for you, your industry or your jobs?

Choosing between an excavator and skid steer is determined by several factors, including the nature of the project, site constraints, and specific requirements. Here's a summary to help you make the right decision:

- Nature of the Task: Determine whether you need precise digging capabilities or versatile manoeuvrability.

- Space Constraints: Assess the size of the work area and whether it requires a compact machine.

- Attachment Needs: Consider the range of attachments required for the job and the compatibility with each machine.

Ultimately, the choice between a skid steer and an excavator depends on the specific requirements of your project, the nature of your industry and your budget constraints. Consulting with equipment experts and considering the factors mentioned above will help you make an informed decision that maximizes efficiency and productivity on the job site.

Shop for your Mini Digger & Excavator with Rhinox

Rhinox offer a whole range of digger buckets, attachments and quick couplers for machines from 0.75 ton compact mini excavators up to 25 ton excavators. Our full range of products are handcrafted from heavy-duty steel and feature additional layers of steel in areas of high wear for extra protection. With over 20,000 products in stock at one time, you can have your order within 4 to 7 business days so you can keep your downtime to a minimum. Shop our full range of products today.

Learn more with Rhinox:

|

|

|